Integration of DGA monitors for more comprehensive transformer monitoring systems

The wait for new transformers means that operators of old units may need to extend their operational lifetime further than originally planned.

The current situation with transformer procurement lead times has increased the criticality and importance of transformers in operation, while heightening the relevance and usefulness of continuous monitoring as a tool for asset management. At the same time, the growing pool of assets in need of condition monitoring continues to increase as early indication against failures is essential to grid uptime.

The wait for new transformers means that operators of old units may need to extend their operational lifetime further than originally planned. Dissolved Gas Analysis (DGA) can be part of the solution, and especially when done continuously with a dedicated monitor, it is one of the best and more comprehensive transformer condition monitoring tools available.

Critical integration testing must be done for multi-gas DGA monitors with multiple transformer monitoring systems to make sure that the communication protocol implementation is compatible with other systems.

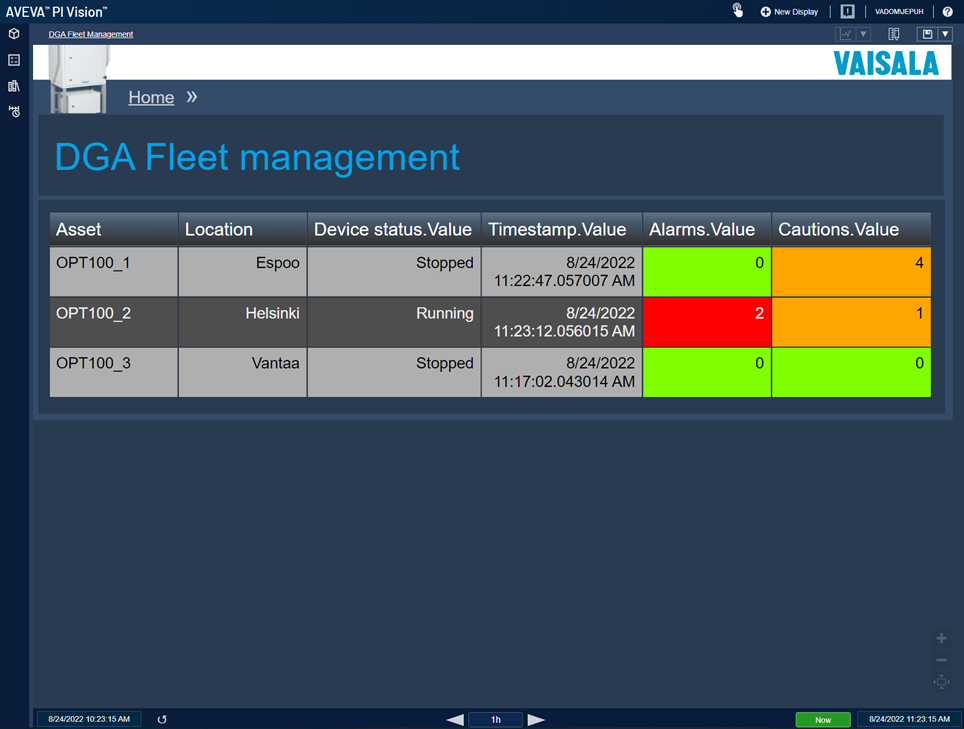

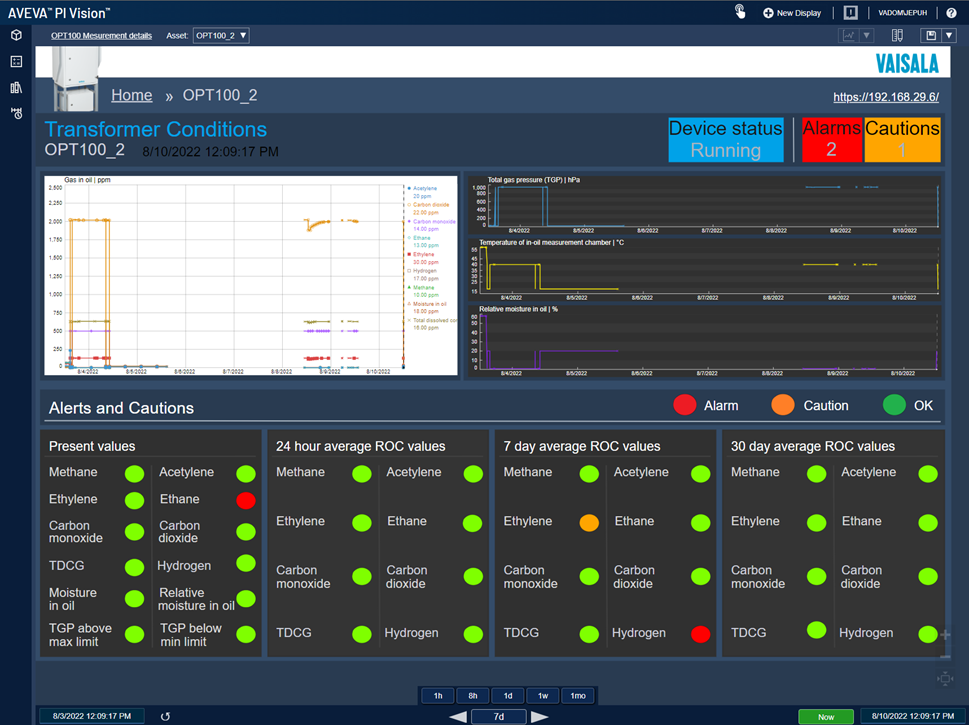

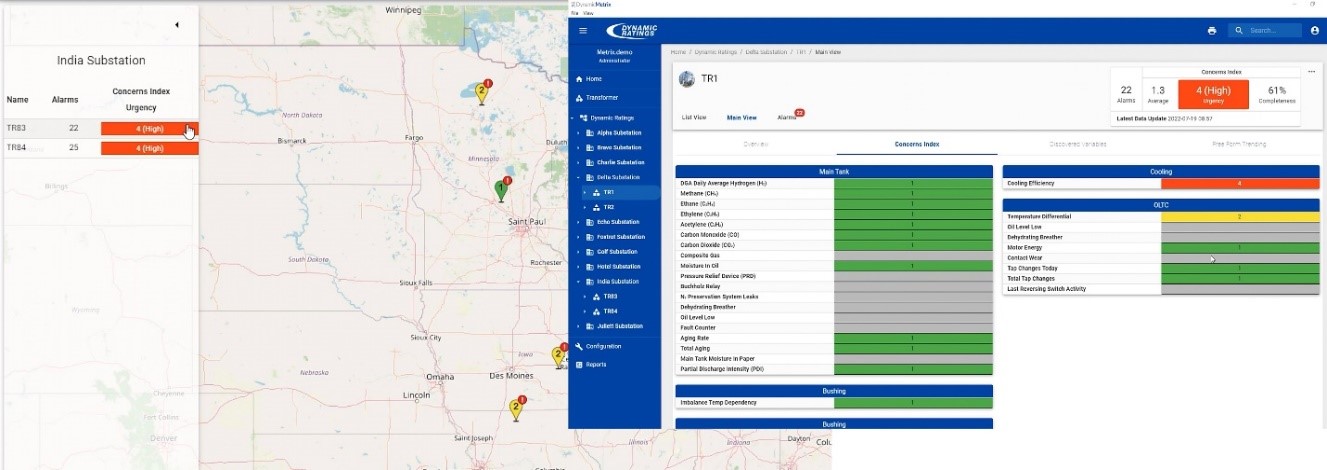

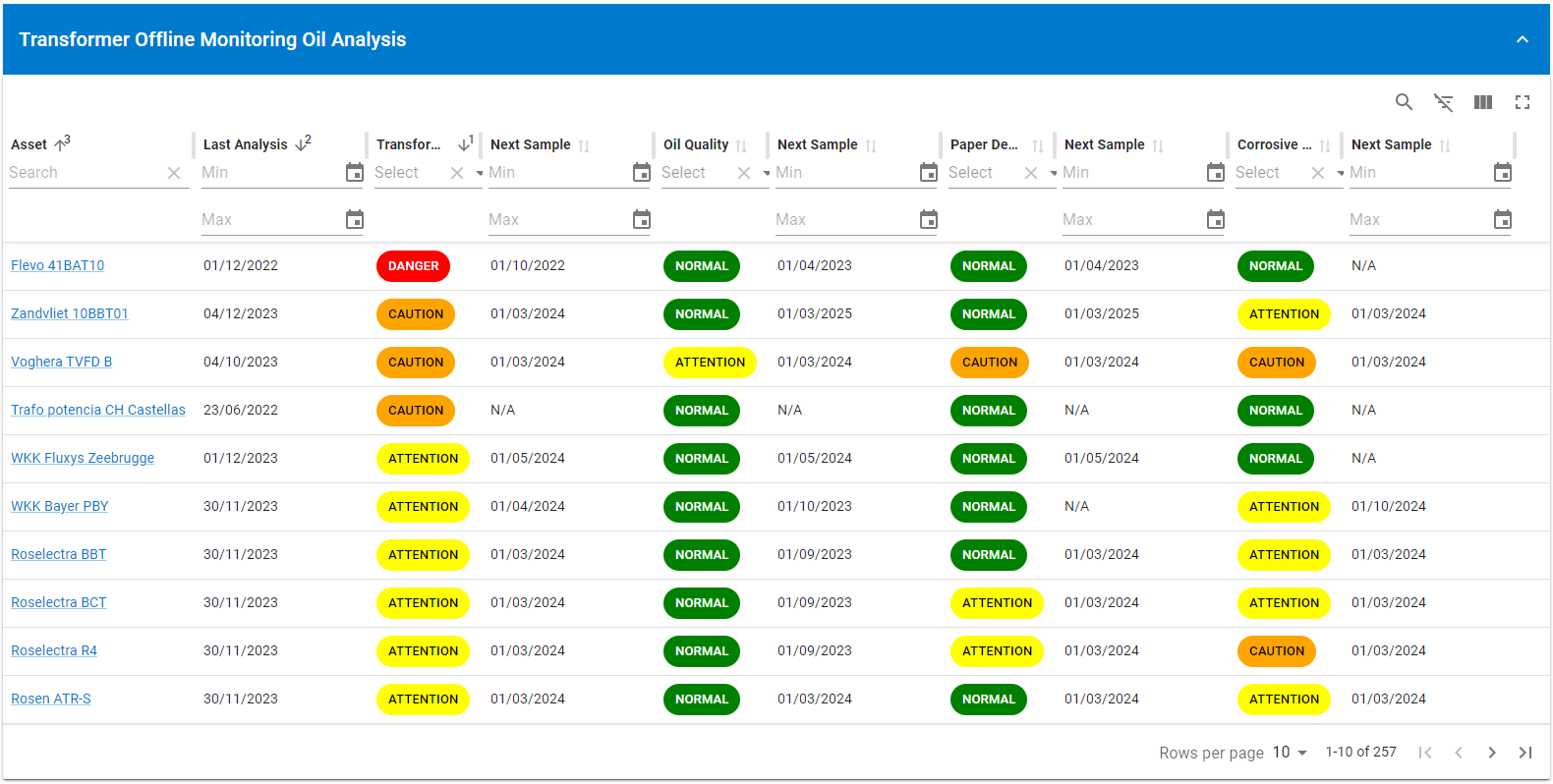

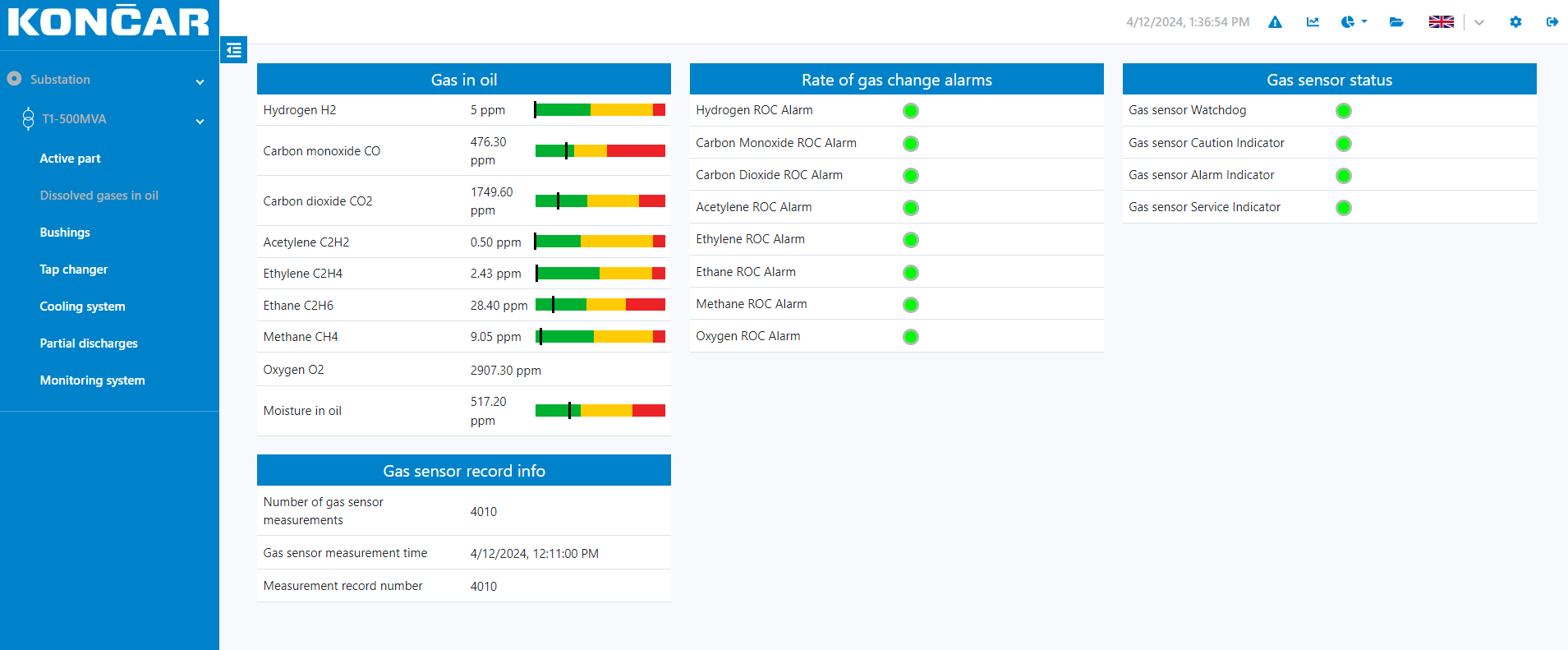

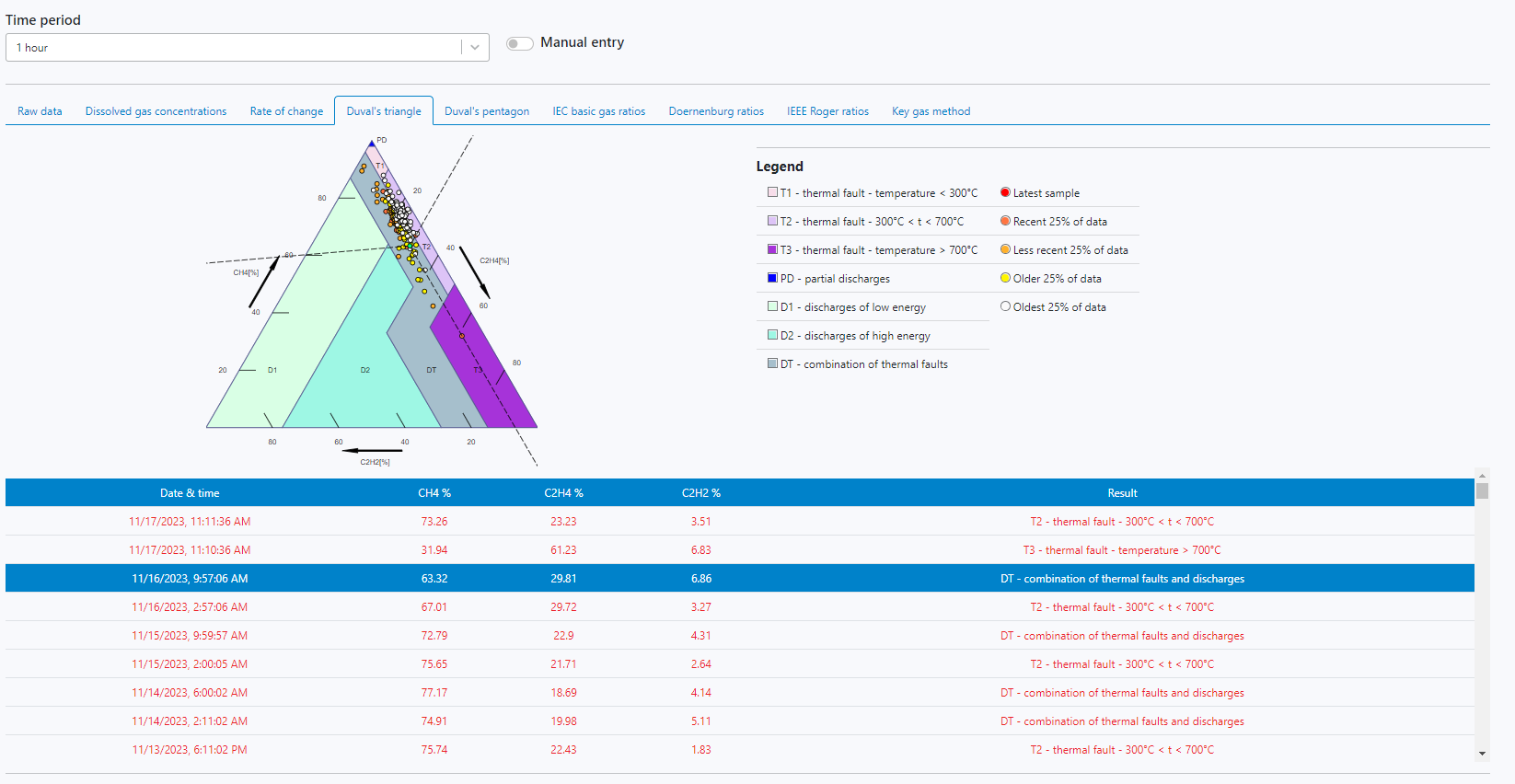

One of the main difficulties reported by utilities in adopting continuous DGA monitoring is handling of the data monitors produce and making sure that alarms and notifications from the monitors are relayed to correct recipients. Many transformer owners are turning toward transformer monitoring systems to improve the collection of data and analytics for the transformer condition assessment as a whole. The systems can also ease generating alerts of issues and directing them to the correct people, whom have the necessary skills and knowledge to react to these situations.

Handling transformer monitoring on a large scale with immense transformer fleets is also driving this interest. Integration of DGA monitors to these systems is one effective way to increase the systems monitoring coverage and implement quick responses to any developing faults detectable by DGA. Correlating the DGA data with transformer loading, oil temperatures and other information complements the analysis and detection of issues. Another advantage of these systems, depending on the implementation, is that the condition monitoring data can be routed separate from operationally critical SCADA data, thus allowing separation of these networks for better cybersecurity.

Contrary to the belief that transformer monitoring systems are closed and only accept certain inputs, many of them allow different DGA monitor manufacturers’ units to be integrated fully into the system. As there is no standard or certified way that monitors should communicate with a transformer monitoring system, there can be slight differences between common protocol implementations (Modbus, DNP3 & IEC 61850) that could cause issues transmitting data. The only way to be certain of inter-compatibility is through testing.

DGA monitor manufacturers can perform integration tests with monitor system makers to verify the compatibility of the monitor and transformer monitoring systems beforehand. This ensures that no surprises of data transmission or data format incompatibility exists between the system and monitor, and that the system can be taken into use without issues.

Critical integration testing must be done for multi-gas DGA monitors with multiple transformer monitoring systems to make sure that the communication protocol implementation is compatible with other systems. This promotes the attitude toward more open systems and ensures that users can utilize DGA monitors, and that data is produced with ease, in the monitoring system of their choice.

There are numerous commercial monitoring systems available for this purpose and each have their own specialties and strengths, so not all compatible systems can be covered, but a few systems and screenshots are presented here.